Air Handling with Humidity Control

SCANCLIME®

Online Monitoring

SCANEYE

Ventilated Cabinets

SCANTAINER-2

Ventilated Cabinet

SCANTAINER EC4RATS

AirShower

Efficient removal of pathogens from clothing or skin when entering your animal facility

Laminar airflow changing cabin ScanFlow

Easy & ergonomic cage changing procedure

Diet/Bedding Handling

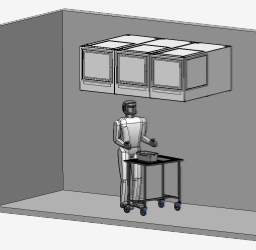

TROLLEYS